据英国广播公司(BBC)网站近日报道,英国科学家通过实验证明,用微波照射可将食物残渣变成重要的化学物质和生物燃料。新方法使人们能在工厂或家里处理废弃的食物,不仅能提供可回收能源,也有助于解决全球范围内食品废弃物日益增多的问题。

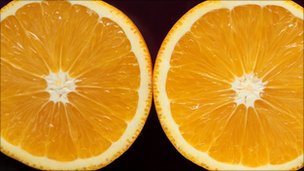

一个橙用于榨汁的部分只占到其一半的比例——剩余部分可用微波处理

英国约克大学的詹姆斯•克拉克教授在日前举办的英国科学节上介绍了该技术,他们计划今年年底在约克建立一个示范装置。他表示,使用高度聚焦的微波,任何有机食物废弃物都可变成有用的化合物,用于材料科学和生物燃料应用领域。

全球很多农场、工厂以及消费者家里都会制造出大量废弃不用的有机废物。例如,在非洲,制造树薯的过程每年都会产生2.28亿吨弃之不用的淀粉;在欧洲,生产咖啡每年会产生30亿吨废物。英国的大部分废物来自于农业残渣,包括废弃不用的树叶、秆、谷类植物和农作物的外壳等。在巴西,生产商们制造橙汁时,每年废弃的橙子皮加起来有800万吨。

巴西橘皮开发公司(OPEC)计划引进约克大学研发出的新技术,从橘皮和废物中提取出生物燃料和化学物质。克拉克解释道:“将橘皮切成小块,放入微波场中,让微波场集中(就像使用家用微波炉一样,只不过其能量更高),其就会激活纤维素,诱使它们释放出大量化学物质,例如,其中的一种化学物质柠檬精油可直接用于制造香水或人们急需的其他化学物质,从这些橘皮中提取出的化学物质最终能被用来制造替代石油的生物燃料。”

克拉克表示,该微波技术将能处理包含有纤维素的任何物质,尤其适合处理纸张和卡片。尽管这项技术仍处于测试阶段,但其可被用于处理很多废物而且可应用于各种规模。目前,因为制造微波需要大量能量,对该设备的大小产生了一些制约,但这种微波机器最终能可大可小,既可以在家庭中使用,也可以应用于大规模的工业化生产,同时还非常容易运输。

演示设备将于今年年底建成以测试这个概念,该设备每小时有望处理10公斤废物。研发人员推测,如果这项技术在商业上可行,届时,一台耗资100万美元的设备每小时将能够处理约6吨废物。农场、工厂和家庭产生的所有食物废物最终都能被回收变为清洁的可再生能源和化学物质。

生物探索推荐英文文章阅读:

Microwaving waste food products could be used to produce important chemicals and biofuels, new technology has shown.

The methods would potentially allow food waste to be processed at home and on an industrial scale.

The technology could provide a renewable source of carbon, as well as addressing the growing problem of global waste.

Professor James Clark of the University of York unveiled these plans at the British Science Festival in Bradford.

Using highly focused microwaves, the scientists believe they can input any organic waste, and extract useful chemical compounds that can be harnessed in materials and biofuel applications.

An international group of scientists have been working together to develop this technology, and they plan to build a demonstration facility in York later this year.

Future is orange

Waste is an unavoidable product of the increasingly complex processes of global food supply, with unused organic residues being produced in vast quantities at the farm, in the factory, and by the consumers themselves.

For example, in the production of cassava in Africa, 228 million tonnes of unused starch are produced each year, and the coffee grounds produced in Europe account for three million tonnes of waste a year. Much of the UK's waste comes from agricultural residues - the unused leaves and stalks and husks of cereals and farm crops.

In the commercial production of orange juice in Brazil, only half of the fruit is used, leaving the rest as waste. This orange peel makes up eight million tonnes a year of waste.

The project OPEC, or the Orange Peel Exploitation Company, plans to ultimately bring the new technology developed at the University of York to Brazil, where fuels and chemicals can be derived from this orange peel waste.

Professor Clark explained: "You dice the peel, put it into a microwave field, focus that microwave field as you would do with a domestic microwave, but at a much higher power. The microwaves activate the cellulose, triggering the release of a lot of chemicals."

One of these chemicals, called limonene, can be used directly in fragrances or contributing to making other highly-desired chemicals.

These orange peel-derived chemicals could ultimately be used to make many of the materials and chemicals that we currently rely on oil for.

Flexibility

Although the technology is still in testing, Professor Clark is optimistic about its potential to be used on all kinds of waste and on a range of scales.

The microwave technology would be able to process anything with cellulose in it, and works particularly well with paper and card.

They say it should be possible to put a range of waste types together into the machine and still extract useful substances.

The demonstration facility will be built later in the year to test this concept, and they expect to be processing 10kg of waste per hour.

If and when the technology becomes commercially available, the developers estimate that a machine costing around £1 million would be able to process around six tonnes of food waste per hour.

There is a limit to the maximum size of facility that can be built, because of the energy needed to make the microwaves, but OPEC hope the microwave machines may eventually be very flexible in size - usable in domestic to large scale industrial scenarios - and also transportable.

It is unclear whether this can become a carbon neutral process, but ultimately, all food waste produced at the farm, industrial, and domestic scales could be reused and recycled into clean renewable sources of carbon and chemicals.